PUMP PARTS

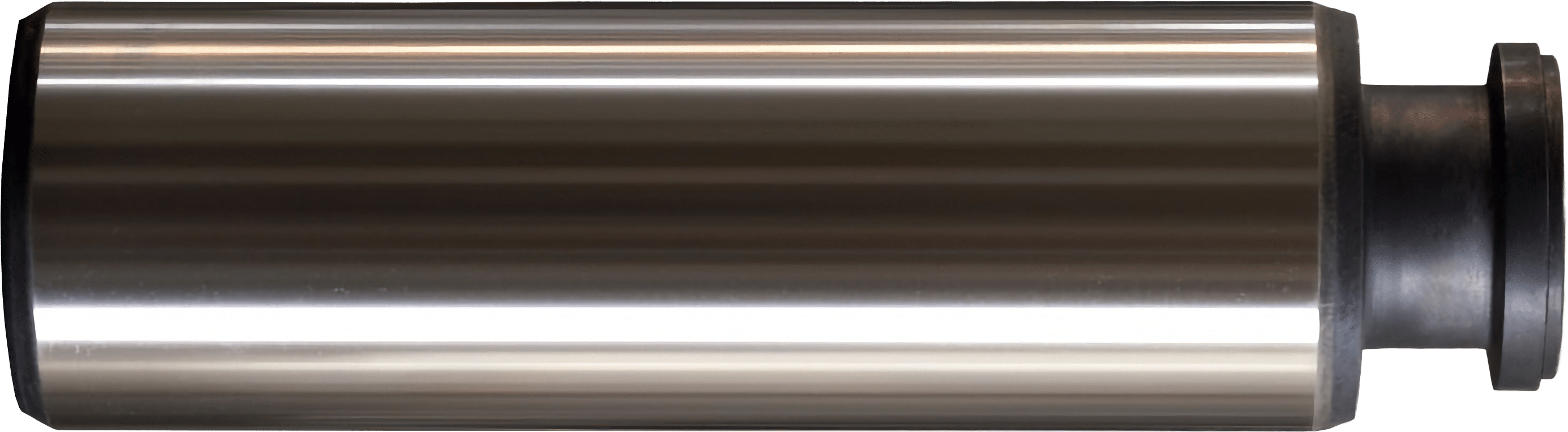

PLUNGERS

In today’s high-pressure pumping applications, plunger quality is absolutely critical.

Plungers face extreme stresses from high pressures, abrasive environments, and corrosive fluids. Using the right materials, like nickel or nickel-tungsten coatings, ensures superior wear resistance and longevity, enhancing pump performance. Poor-quality plungers lead to failures, increasing downtime and costs. Precision manufacturing ensures each plunger meets exact specifications, guaranteeing durability under harsh conditions. Choosing the right materials and craftsmanship reduces wear, cuts maintenance, and maximizes pump lifespan.

DR3 PLUNGERS

DURABILITY AND RELIABILITY

Our plungers are designed to withstand the harshest conditions, providing unmatched durability and reliability:

- Nickel and Nickel Tungsten Options: Ensuring superior wear resistance and extended service life.

- Compatible with All Legacy and Modern Era Fluid End Styles: Our plungers are versatile, fitting a wide range of systems.

- Rework Plunger Program: Reduce costs by refurbishing your used plungers.

- Available in All Sizes: Customizable to meet the specific demands of your operation.

PLUNGER

REWORK

PROGRAM

Swipe Bar

At DR3 Machine

We understand that in today’s pressure pumping market, every cost-saving advantage matters.

That’s why we offer the DR3 Rework Plunger Program, transforming used plungers into like-new components at a fraction of replacement costs. We rework, respray, and restore plungers to exact specifications, delivering high-quality, cost-effective solutions without sacrificing durability or performance, keeping you ahead in a competitive industry.

STAY RODS

STAY RODS

At DR3 Machine, we offer a complete range of OEM compatible stay rods designed to meet the needs of both legacy and modern fluid end pump mounting. Our single-piece stay rods are ideal for traditional fluid end mounting, providing reliable performance for countless and familiar setups. For several high-horsepower pumps, we offer the innovative two-piece stay rod design, which delivers enhanced strength and durability under extreme conditions.

One of our standout features is the ability to copper coat stay rods threads of any stay rod upon request.

Copper’s self-lubricating properties significantly reduce the risk of the all too common stuck stay rod, ensuring a smoother removal process when it’s time for maintenance. This makes copper-coated stay rods a smart choice for operations that need efficient, reliable performance.

Read More

Additionally, all of our stay rods are manufactured with rolled threads, offering superior strength and durability compared to the outdated cut thread method. As the industry has moved toward rolled threads for their ability to handle higher stresses, and at DR3 Machine, we ensure every stay rod meets these rigorous standards, offering enhanced longevity and performance for your pumps.

At DR3 Machine, we manufacture stay rods that combine strength and precision, ensuring your pump operates at peak performance:

- 4340 Material: Known for its toughness and resistance to fatigue.

- In-House Rolled and Gauged Threads: Guaranteeing precision and long-lasting connections.

- One-Piece Stay Rods in both 2” and 1 ¾” options, as well as Two-Piece Stay Rods in the same sizes for flexible configurations.

- Thread Options: Shot peened, plated, or coated for enhanced durability.

PONY RODS

PONY RODS

We apply the same precision and expertise from our plungers to our pony rods.

With decades of experience, we have a proven track record of crafting pony rods that are not only durable but also fully compatible with any OEM pump operating in today’s demanding pumping environment. Our ability to manufacture all styles of pony rods ensures that you receive components that meet exacting standards and fit seamlessly with your existing equipment.

Read More

Poor-quality plungers can lead to premature failure, increasing downtime and repair costs. Expertise in precision in-house manufacturing also plays a crucial role—ensuring that each plunger is made to exacting specifications, with the right coatings and treatments, guarantees its durability and ability to perform consistently under harsh conditions. Selecting the right plunger with the proper material and expert craftsmanship makes all the difference in minimizing wear and tear, reducing maintenance needs, and maximizing the lifespan of your pressure pumping systems.

OUR PONY RODS ARE

Crafted for durability and performance under extreme conditions:

- Nickel Coated: Providing enhanced corrosion resistance.

- Rework Pony Rod Program: A cost-effective solution for extending the life of your pony rods.

- Capability to Make All Styles: We can manufacture pony rods to fit any pump system.

Whether you need enhanced durability, corrosion resistance, or precise OEM specifications, DR3’s pony rods deliver reliable performance under tough conditions. With nickel-coated options and a rework program, we offer comprehensive solutions that exceed industry standards.

OTHER PUMP PARTS

At DR3 Machine, our state-of-the-art machine shop is specifically equipped to expertly manufacture a wide range of Pump and Fluid End parts. We pride ourselves on maintaining critical tolerances to ensure the perfect fit and function of every part, no matter the application. Our experience spans across multiple OEM pump systems, allowing us to deliver parts that meet the unique specifications of each system.

From packing nuts to gauge connections and discharge flanges

We understand the nuances and technical demands of each component we produce. Our team’s in-depth knowledge of pump applications, combined with rigorous quality control systems, guarantees that every part exceeds industry standards for reliability and performance. Whether you need new parts or want to extend the life of your existing equipment, DR3 Machine provides the quality and precision you can trust to keep your operations running smoothly.

Our lineup of

OTHER PUMP PARTS

PACKING NUTS

SUCTION AND DISCHARGE COVERS

GAUGE CONNECTIONS & RETAINER NUTS

DISCHARGE FLANGES AND BLINDS

OPTIMIZE YOUR PUMPS WITH PRECISION ENGINEERED PARTS

Precision-crafted pump parts designed for durability, reliability, and cost-efficiency in every operation.